OSHA HCS: Physical and Health Hazard Classification Updates

OSHA Published Hazard Communication Standard (HCS) Series

Blog Post 2: Physical and Health Hazard Classification Updates

Last week, CHEMTREC posted it's comprehensive insight into the Occupational Safety and Health Administration (OSHA) published Hazard Communication Standard (HCS). This week, we cover hazard classification updates: Clarification update to the language of Paragraph (d)(1), Physical Hazards and Health Hazards.

Learn more by checking out CHEMTREC's full blog series for OSHA HCS Updates:

- Week of May 30 – Comprehensive Insight on OSHA HCS Updates

- Week of June 3 – HCS Updates: Physical and Health Hazard Classifications- this post

- Week of June 10 – HCS Updates: Allocation of Elements and Labels

- Week of June 17 – HCS Updates: Safety Data Sheets

- Week of June 24 – HCS Updates: FAQ on OSHA’s Revised Hazard Communication Standard

Hazard Classification

In Paragraph (d)(1), the requirements for chemical manufacturers and importers are outlined for the classification of chemicals, while Paragraphs (f) and (g) cover requirements for labeling and safety data sheets (SDSs). Although separate, these paragraphs are related, particularly after OSHA’s aligning of the HCS with the Globally Harmonized System of Classification and Labeling of Chemicals (GHS) in 2012. Prior to this, OSHA requirements for labeling and SDS were more performance oriented but the shift to GHS introduced more prescriptive labeling and required all hazards to be identified. This was an issue because the chemical hazards, as packaged by the manufacturer, differed from the hazards that were generated under use by downstream users. Manufacturers questioned how they should present the information on the label and the SDS.

To address this issue, in the OSHA final rule, the language has been updated to (d)(1):

- Acknowledges the hazard classification must include all hazards associated with the chemical’s “intrinsic properties”.

- Breaks down (d)(1) into (d)(1)(A) and (d)(1)(B) to differentiate the chemical hazards for the chemical as shipped (including changes in physical form) and hazards associated with chemical reaction products (known or reasonably anticipated) in downstream applications. OSHA believes this provides clarification on what hazards must be addressed and provides the necessary guidance on the information that needs to be on the label and the SDS.

OSHA indicated that this change reiterates the scope language under (b)(2) and OSHA’s longstanding position that hazard classification must even cover hazards created by chemical reactions that occur during known or reasonable anticipated uses.

OSHA also discussed this extensively in the preamble of the revised Hazard Communication Standard, outlining not only when an upstream manufacturer must consider downstream use but also when that use would either be unknown/reasonably anticipated or when the downstream user becomes the manufacturer of a new chemical. OSHA does not consider that a manufacturer or supplier would be able to know or reasonably anticipate a downstream use if the downstream user uses the chemical in a proprietary process, producing derivatives that are trade secrets. In this case, the downstream user becomes the manufacturer.

Physical Hazards

Changes were made to improve the communication of hazards, such as realigning categories and adding new ones like desensitized explosives. The main changes can be found in flammable gases, aerosols, and oxidizing solids.

Explosives

OSHA has added two notes to the Explosive Hazard Class:

*Note 1: Acknowledges the new hazard class of Desensitized Explosives (B.17).

*Note 2: Indicates that a chemical may still have explosive properties even though they were exempt from classification as an explosive. In these cases, these properties must be communicated on the SDS.

One commenter noted that the GHS made major revisions to the Explosive Hazard Class classification criteria in GHS Revision 9. While OSHA declined to adopt the classification criteria from the revision due to lack of notice, OSHA did explain there is already flexibility built into the labeling for explosives and that in many cases following the GHS Revision 9 updates will result in full compliance with the HCS.

Flammable Gases

OSHA made significant changes to the Flammable Gases Hazard Class:

- Added two subcategories to this hazard class, pyrophoric gases, and unstable gases. The criteria indicated that if the gas is either pyrophoric or unstable it is also considered a category 1A flammable gas.

- Added a new subcategory 1B Flammable gas. Category 1B flammable gases fall into category 1 but have a lower flammability limit or a lower burn velocity.

- Since OSHA has added pyrophoric gases to the Flammable Gases Hazard Class, OSHA has now removed pyrophoric gases as a stand-alone hazard class.

Aerosols and Chemicals Under Pressure

OSHA also made significant changes to the Aerosol Hazard Class (formerly known as Flammable Aerosols).

- Added non-flammable aerosols to this hazard class. OSHA found that many aerosols also fell under Gases Under Pressure. This resulted in over warning on aerosol canscans, and it potentially dilutes the warning on gas cylinders.

- OSHA noted that chemicals under pressure were often the same chemicals in aerosols resulting in similar hazards but were in refillable containers which created a potential inconsistency in hazard warnings. In theis revised Hazard Communication Standardfinal rule, OSHA adopted the nomenclature Chemicals Under Pressure.

Gasses Under Pressure

Updated to acknowledge that aerosols are not additionally classified as gases under pressure.

Flammable Liquids

Updated to acknowledge that aerosols should not additionally be classified as flammable liquids. OSHA has also updated the additional classification considerations to acknowledge flash point determination methods under 29 CFR 1910.106.

Flammable Solids

Updated to acknowledge that aerosols are not additionally classified as flammable solids.

Self-Heating Chemicals

OSHA added a note under the criteria indicated that classification of solid chemicals must be performed on the chemical in the specific form in which it occurs in the workplace.

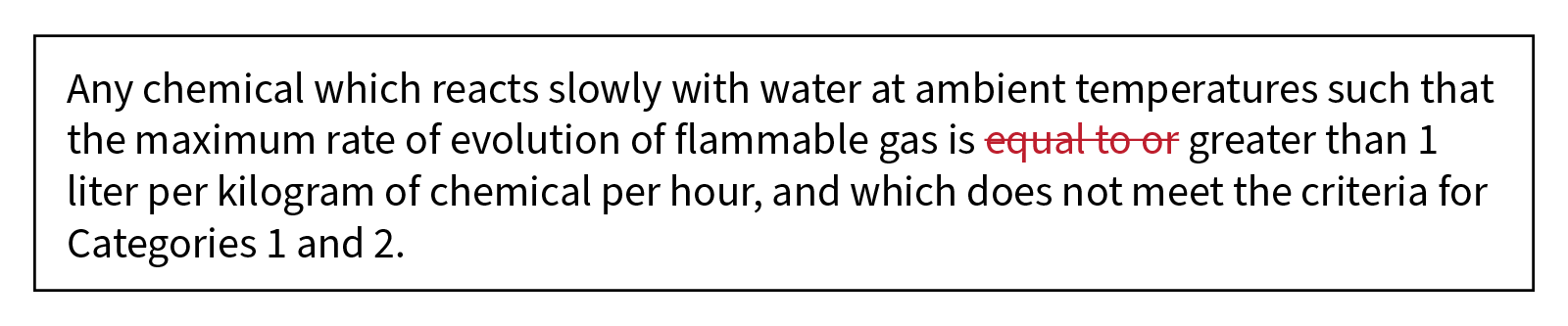

Chemicals Which, in Contact with Water, Emit Flammable Gases

OSHA updated the criteria for category 3 to remove the term “equal to or” to read:

Oxidizing Gases

OSHA updated the Oxidizing Gases hazard class to include the new test O.3 (since the material for test O.1 is no longer available). No retesting needs to be done since data from either test is acceptable for classification purposes.

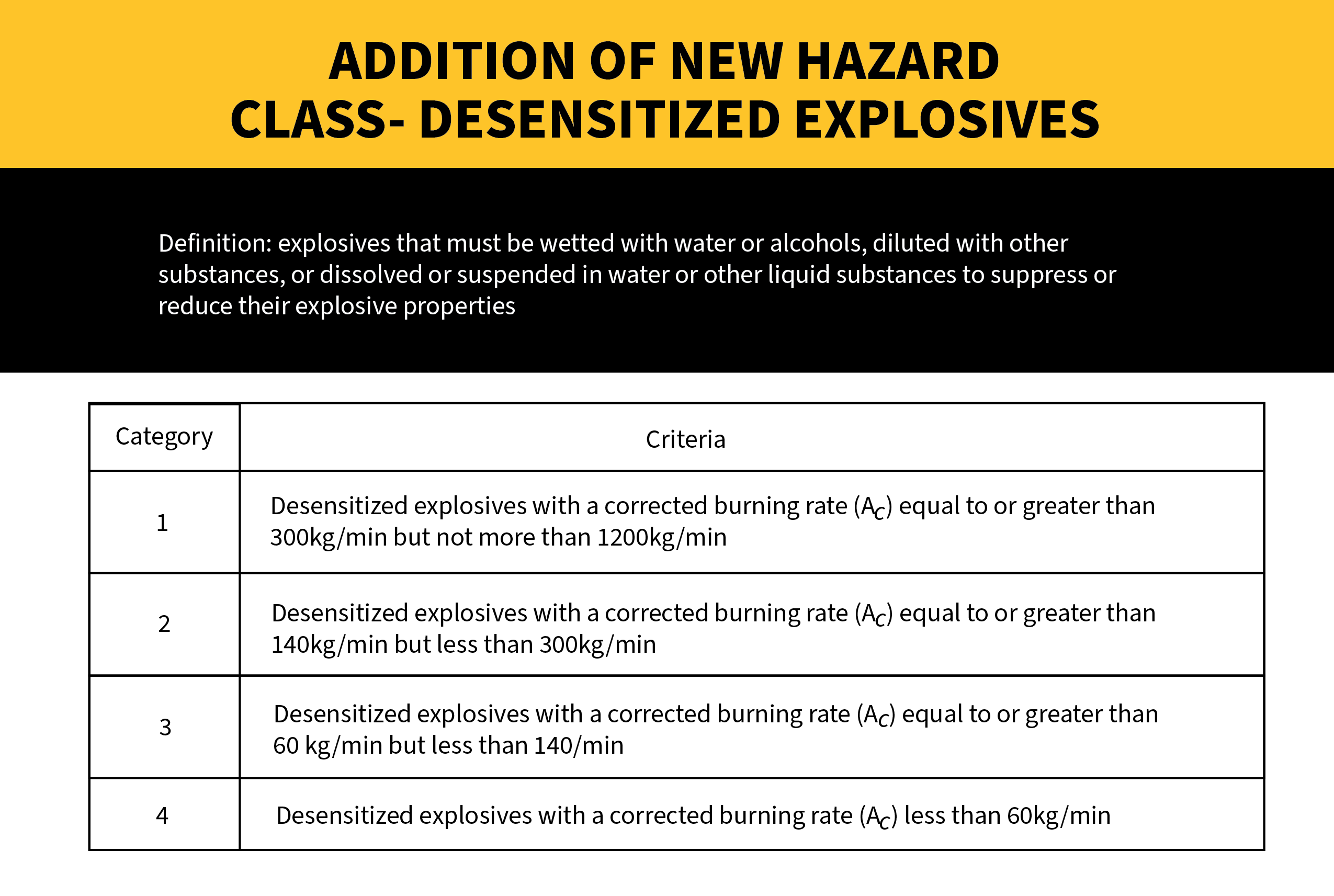

Desensitized Explosives

This hazard is another newly adopted OSHA hazard class.

Health Hazards

While there were some significant changes to several of the OSHA health hazard classes, OSHA does not expect major (if any) changes in the classification of existing chemicals.

Definitions

More general and neutral definitions are updated to provide clarification with respect to test guidelines (by removing guideline criteria from the definitions). For example, OECD test guidelines were removed from the definitions and moved to paragraphs outlining classification criteria. OSHA updated all the health hazard definitions to reflect these parameters.

Acute Toxicity

Some clarifying changes to the Acute Toxicity hazard class were made to align with GHS Revision 7. These changes include acknowledged newer in vivo methods can be used to assign acute toxicity categories, updated presentation to Table A.1.1 and corrections to cross references.

Corrosive to the Respiratory Tract

OSHA clarified in Acute Toxicity hazard class that when classifying “corrosive to the respiratory tract” it should only be classified under acute inhalation toxicity if the data is based on lethality. OSHA is retaining the provision that if the classifier has data that indicates corrosion of the respiratory tract and the effect does not lead to lethality, then the hazard must be addressed in the STOT-SE (A.8) hazard class. If there are insufficient data to classify the hazard as STOT, and the classifier determines based on relevant skin and/or eye data that the chemical may cause corrosion of the respiratory tract, then the hazard statement “Corrosive to the respiratory tract” must be used in A.2 and/or A.3, as appropriate.

Unknown Acute Toxicity

OSHA updated a note to clarify the statement that “X” percent of the mixture consists of ingredient(s) of unknown acute (oral/dermal/inhalation) toxicity on the label and the SDS must be differentiated by route of exposure.

Skin and Eye Hazard Classes

Skin Corrosion and Skin Irritation

OSHA finalized Appendix A.2 to reflect the updates to GHS Revision 8.

Serious Eye Damage and Eye Irritation

In updating this hazard class to align with GHS Rrevision 7, one of the major clarifications was how to use pH data to clarify that high acid/alkaline reserve or no data for acid/alkaline reserve should be considered when the pH is ≤2 or ≥11.5. OSHA also proposed modifications to the footnotes of Figure A.3.1 to reflect the most recent test methods.

Germ Cell Mutagenicity

OSHA removed the Mouse Spot Test (OECD 484) as an example of an in vivo somatic cell mutagenicity test.

Reproductive Toxicity

OSHA removed the reference to “breastfed babies” and replaced it with “classification for effects via lactation” to differentiate between effects that can interfere with lactation and substances and their metabolites that may be transmitted through breast milk to children in amounts sufficient to cause concern for the health of the breastfeeding child.

Relevant Ingredients

OSHA updated several hazard classes to clarify the use of relevant ingredients.

Specific Target Organ Toxicity (STOT) Single Exposure

OSHA added a new paragraph explaining that when using the additivity method for category 3 a relevant ingredient in a mixture is one that is present in concentrations greater than 1% (unless there is reason to suspect that an ingredient is relevant below 1%).

Aspiration Hazard

OSHA added a new paragraph to clarify the concept of relevant ingredients and that relevant ingredients are those present in concentrations of at least 1%.

For more details about what the Hazard Communication Standard includes, view the OSHA Hazard Communication Standard pdf.

Have questions? Submit your questions to our SDS team at SDSsolutions@chemtrec.com by June 21 to be answered in an additional blog post.

Please note: These are the author’s opinions and should not be taken as OSHA’s interpretation nor do they represent legal advice. Readers should consult with a qualified attorney for advice on a specific legal issue. The information provided is based on the author’s understanding of the regulation at the time of writing. This blog’s main purpose is to inform readers of the published Hazard Communication Standard. To keep up with OSHA’s latest updates on the final HCS rule, follow CHEMTREC on social media: Facebook | X | LinkedIn

Request a Quote for SDS Authoring

Interested in SDS Authoring? We work with companies of all sizes and create Safety Data Sheets in several languages. Complete a request and we'll be in touch soon!

Contact Our Sales Team

Interested in chatting right now? Email our team at sales@chemtrec.com or call us at 1-800-262-8200, option 3, Monday through Friday, 8:30am-5:30pm ET.